From concept to 'first beam', Buckley Systems Limited provides exceptional end-to-end design, engineering and integration solutions for magnetic systems.

Precision Manufacturing

From the smallest to the largest magnet, Buckley Systems Limited delivers unparalleled manufacturing capability with precision and speed via a powerful combination of people and plant.

We have more than 34 CNC machining centers in our machine shop, spread over a 18,000m2 workshop. Our investment in machining capability is about more than just purchasing the largest, most advanced CNC equipment – we also hire and develop a large team of highly skilled operators. The depth of this in-house machining capability streamlines the manufacturing process and provides our customers with the best product faster and with less risk.

SCALE, PRECISION, AND SPEED

We can manufacture among the largest analysing and scientific magnets (many tens of tonnes) through to devices you could hold in your hand.

Our manufacturing precision is world-class, and trusted by industry and research institutes alike. Using our latest CNC milling equipment (such as the recent V100), EDM wire cutters, and precision grinders, we can tailor a manufacturing technique to achieve critical tolerances. We’re trusted by national laboratories like TRIUMF to machine their cutting edge spectrometer systems.

Finally, our infrastructure gives us unrivaled capacity, so we can offer unbeatable delivery times.

POWERED BY PEOPLE

We employ over 90 dedicated CNC operators. Since we are focused on the particle accelerator systems, our operators have a depth of industry specific knowledge. Merely owning a machine isn’t enough - by investing in training and development, we can push our tools to achieve every last micron of tolerance.

POWERED BY INNOVATION

Hand in hand with our people investment, we regularly innovate on production techniques in order to meet the exacting requirements of our customers. For example, we have invested in friction stir-welding technology to produce unparalleled vacuum quality welds in aluminium.

We pioneered a highly efficient and precise method of producing laminated multipole magnets using laser cutting and EDM machining. Obtaining 6-micron tolerances on assembled multipole magnets may have been thought infeasible, until Buckley Systems Limited did it.

WE DO IT ALL

Plating, welding, finishing: we take care of all the ancillary processes. We also manufacture all coil formers, jigging, tooling, even the test equipment associated with producing product – all in house, with our characteristically high level of care and attention. You typically don’t see this process, but it’s critical to the quality and repeatability of the finished product. We also draw on the experience of a network of trusted suppliers for exotic manufacturing techniques such as electron beam welding or robotic laser welding.

RAW MATERIALS ADVANTAGE

Most manufacturers order iron on a batch basis, which can lead to inconsistency in quality and lead times. Such is the volume of iron we consume, we have a standing order at our supplier foundry for ‘Buckley recipe’ iron called BSL1006. This means we have consistent, reliable and known iron quality, with fully characterised magnetic properties.

Quality

Buckley Systems Limited products are critical components of medical radiotherapy devices and business-critical semiconductor implanters. As such, we have a dedicated quality team and measurements laboratory to ensure we deliver the highest performance and reliability.

THE RIGHT PROCESSES

Buckley Systems Limited quality systems are built on an ISO 9001 framework. That allows robust process control and full traceability from drafting through to shipping.

Through decades of working with international customers across varied industries, we know that one size does not fit all. We will work with you to develop a quality and testing plan, including mechanical inspection, functional tests, and a documentation package tailored to your systems and needs.

A UNIFIED TEAM

Our quality and measurement team is closely linked to our design and physics capability. Because of our depth of experience with particle beam systems, we understand the significance of the measurements we’re taking. That means we can help you develop a robust measurement plan and carry it out to the highest level.

QUALITY FACILITIES

Buckley Systems Limited has developed a quality and measurement laboratory, set in a temperature-controlled area. Our facilities include a suite of fully calibrated mechanical metrology and magnetic measurement equipment.

MECHANICAL METROLOGY

We use high-precision co-ordinate measuring machines (CMM) to measure parts and assemblies. Our operators are highly trained and bring the experience required to develop robust measurement plans and carry them out consistently.

MAGNETIC MEASUREMENT

Buckley Systems Limited develops specialty magnetic measurement equipment. Our 3D field mapping and rotating coil testing stations incorporate high stability power supplies (up to 3000A), DCCTs, Group 3 Gaussmeters, 3-axis stages with linear encoders, and custom rotating coils of various apertures.

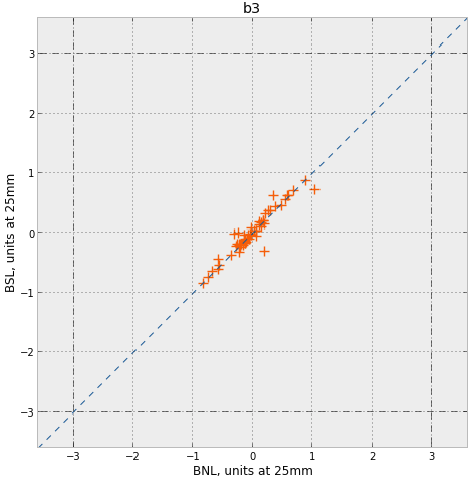

Buckley Systems Limited tested 90 multipole magnets for Brookhaven National Laboratory's (BNL) NSLS-II Synchrotron light source. Multipole coefficients were measured to 22nd order and down to parts per million of the fundamental. These were independently verified to be consistent with BNL’s best-in-world magnetic measurements.

This graph compares BNL and Buckley Systems measurements of the B3 coefficient of quadroples. Points represent magnets and dashed square shows specification.

Electromagnet Coils

For even the most demanding of electromagnet coil applications, we are always able to find reliable and optimised solutions for this critical component.

TRIED AND TRUE

For over three decades, we have been manufacturing copper electromagnet coils. Our coil shop has developed robust and consistent techniques for this specialised product. Your coils will be manufactured with extensive knowledge of materials and forming, resins and fillers, vacuum impregnation and tooling. That means you get proven quality, longevity and consistency.

SPECIALIST DESIGNERS

Whether working from scratch or optimising an existing design, our team of specialist coil designers can contribute extensive input into coil design. We will find optimum solutions based on requirements like current density, efficiency, physical tolerances, manufacturability and tooling costs, reliability, cooling restrictions, and thermal characteristics - always with a goal of providing the best value coils.

EXTENSIVE REPERTOIRE

Buckley Systems Limited has manufactured a huge range of different coil types. Whether your copper coil design is basic or exotic, grams or tons, from one-off prototypes to production runs, Buckley Systems Limited has the skill and capacity to deliver.

COIL TYPES

Solid conductor coils are an excellent choice for low power-density designs, as they are simple and cost-effective.

Strip wound coils are a Buckley Systems Limited specialty, being highly reliable and consistent, and offering excellent price-performance characteristics.

Hollow-conductor coils can be formed into any geometry, for the most demanding applications.

A range of vacuum encapsulation, potting and casting techniques are available for both coils and entire assemblies. Epoxy vacuum impregnation produces mechanically robust composite structures that stand the test of time.

FULLY TESTED

Coils are carefully examined, tested and documented throughout the production process to ensure defect free operation and traceability. A suite of calibrated test equipment allows us to test coils for interturn shorts, ground insulation resistance, resistance, inductance, flow, pressure drop and thermal performance under operational conditions.